Vitesco Tech, Cebi Grp Working Together

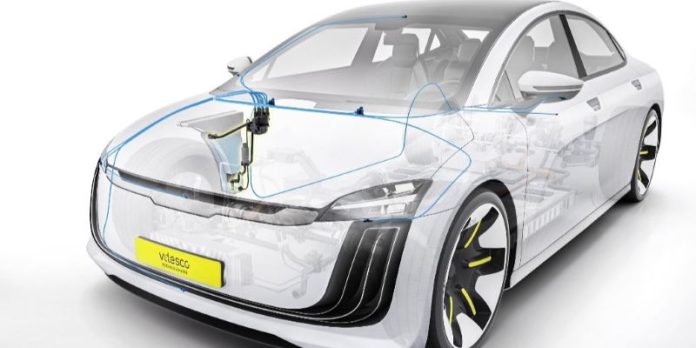

ASCS can keep more than 10 environmental sensors clean with water using just a single infrastructure.

MUMBAI, Aug 30 (The CONNECT) – Vitesco Technologies, a global manufacturer of advanced powertrain technologies and electrification solutions and Cebi Group, a specialist in washer systems, are partnering to develop the Advanced Sensor Cleaning System (ASCS), a highly integrated all-in-one solution that can keep more than 10 environmental sensors clean with water pressure of up to 7 bar, using just a single infrastructure.

This addresses an important requirement for autonomous electric driving: Environmental sensors such as cameras and lidars must be kept free from dirt and adverse effects caused by wind and weather conditions for the safe execution of the autonomous driving function – and thus also of the powertrain.

As future autonomous vehicles will generally be electric, the connectivity between the sensor and the electric drive is a key subject for this partnership.

A single high-pressure pump is sufficient to supply several sensors, and with lower water consumption, said Robert Paul, head of Actuators business unit, Powertrain Solutions division at Vitesco Technologies.

Thanks to its high degree of integration, it is also very easy and economical to accommodate in the vehicle, he said.

Etienne Jacqué, head of R&D at Cebi Group, combining our globally successful technology for washer systems with the electronics and electromechanical expertise of Vitesco Technologies creates a complete system that is a key enabler for autonomous electric drive systems.”

Vitesco Technologies supplies three core components for the new sensor cleaning system and ensures functional integration: A brushless and compact high-pressure pump with 2 to 7 bar delivery pressure provides the cleaning water for the complete sensor equipment of a vehicle. A special distributor redirects the flow from the pump to the correct sensor. The control electronics also come from Vitesco Technologies.

Cebi Group provides the large reservoir with up to four individual washer pumps for the classic windshield and headlamp cleaning, the complex hosing, the nozzle technology as well as the overall mechanical system integration in the vehicle.

Production is scheduled to start at the end of 2026.